Travelling Formwork System for Free Cantilever Construction

BRIDGEBUILDER Enhance The Economic Performance of Bridge Projects.

Reliable Bridge Construction Equipment for Free Cantilever Construction with NRS Innovation and Solutions.

“BRIDGEBUILDER” FORMTRAVELLER

The Underlane NRS Formtraveller which is widely and well known as the Bridgebuilder, is the most reliable and extensively used FormTraveller system in the world for in-situ construction of free cantilever post tensioned box girder bridges as well as cable-stayed concrete bridges.

It has been adopted as the de facto design that is widely used among all suppliers in the industry.

To date NRS has supplied more than 1000 units of Bridgebuilder worldwide.

The “Bridgebuilder” formtraveller system was invented in 1970 and today it is acclaimed for enhancing the cost-effectiveness of bridge projects worldwide.

The Bridgebuilder has undergone vast improvements over the years and incorporated innovative solutions, making it a developed, practical and reliable system for contractors.

Today the Bridgebuilder is a versatile, lightweight, easy-to-assemble and operate.

The system is designed with the following cost savings solutions:

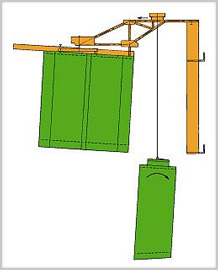

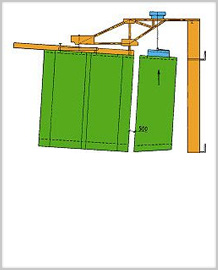

- Special “Fast-Split” installation method on hammerhead as short as 7m long.

- NRS Bridgebuilder with cross member for Hammerheads as short as 3m.

- Back launching to pier for ease of dismantling after use

- Use of Bridgebuilder for casting hammerhead

- Casting closure segment stitches.

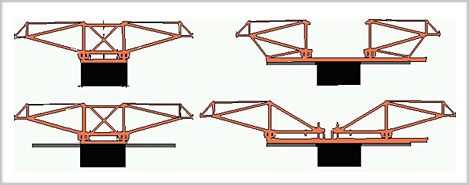

STANDARD CONVERTIBLE BRIDGEBUILDER

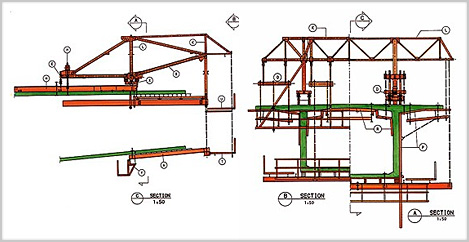

The Standard Bridgebuilder is designed for a maximum segment length of 5 m and load capacities (concrete and formwork) varying from 100 tons to 400 tons. The steel weight depends on the cross-section of the bridge in question, but will normally vary from about 25 tons to 65 tons correspondingly. The Standard Bridgebuilder may be adapted to suit almost any cross-section, and is easily adjustable during operation to variations in segment length (up to 5 m), section height, web thickness, and deck width.

TAILORED BRIDGEBUILDERS

The Bridgebuilder may be tailor-made for segment lengths beyond 5 m and other extreme conditions. Alternatively it may be designed for shorter lengths where the maximum segment length is less than 5 m, and there is a requirement to reduce the weight of the Bridgebuilder for a particular application.

NRS Special Bridgebuilder for arch bridge construction has also been used successfully for the construction of the 323m arch bridge at the Hoover Dam Bypass project – the longest arch bridge in North America and the 4th longest concrete arch bridge span in the world.

Modern bridges are becoming wider and longer but at the same time clients and contractors are seeking shorter construction time. In NRS, pursuing improved and innovative solutions to meet these requirements has always been one of NRS main goals.

NRS never fails in giving innovative designs even for conventional equipment like the Formtraveller

THE BRIDGEBUILDER FEATURES

- Lightweight

The use of rectangular hollow sections in the main structural components and recoverable high strength bars in all stays and ties reduces the total steel weight to a minimum.

- Versatile and Flexible Design

The Bridgebuilder may be adapted to almost any cross-section and is easily adjustable during operation to variations in segment length, box height, web thickness, deck width and road alignment (gradient, curvature, super-elevations).

- Small Deflections

The vertical deflection at the front of the Bridgebuilder is less than 25 mm at maximum load. Formwork beams are designed for a maximum deflection of 1/400 of their length.

- Easy Assembly and Operate

-One Bridgebuilder may be assembled in one week. Rolling forward on rails, the reset time is short.

-Lifting system to lift and install the whole pre-assembled on ground Underlane BB FT.

– Rebar Carrier and trolley system