An advanced, cost-effective, reliable and economical solution for modern bridge construction.

The NRS Movable Scaffolding System (MSS) is one of the most popular and recognized system in the world at present for span-by-span in-situ construction of bridges. The system is renowned for its lightweight, easy to assemble, practical efficiency in operation, and innovative ideas.

The NRS MSS has the ability to adapt to different cross sections allowing the contractor to re-use the equipment for different projects.

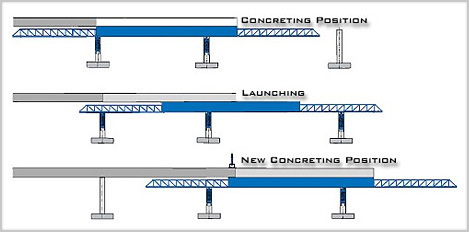

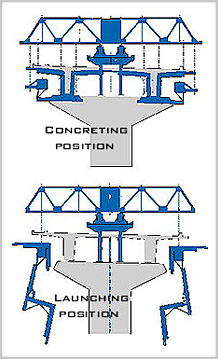

The NRS MSS system consists of a support structure spanning between two piers from which formwork is either supported or suspended. The inner formworks (core form) is collapsible and can run on a rail system to allow easy relocation to the next span. The system is designed so that the outer formwork can be opened sufficiently and adequately to allow to pass around the bridge piers during the launching operation. After launching, the formwork is closed again and after setting to the designed alignment and level, placing of reinforcement can commence.

The NRS MSS system has been further developed over the years and the developments resulted in the reduction the high costs of construction manpower.

Today our widely proven MSS for construction of cast-in-situ bridges can many cost saving advantages to bridge construction through:

- Optimized design

- Ease of assembly

- Efficient operation

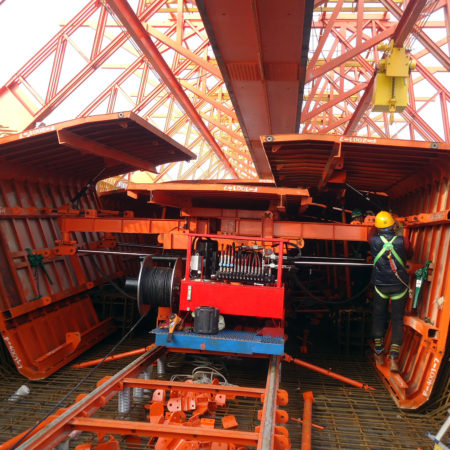

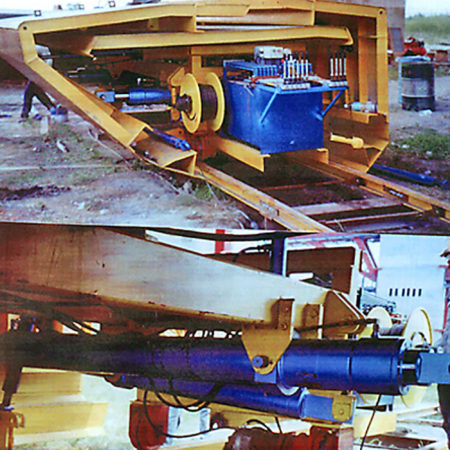

One of the latest innovation enables the Underlane Type MSS to operate without the need for external cranes or lifting equipment. The system is most suitable for bridges over waterways, bridges with high piers as well as for site conditions where access for external cranes is difficult.

NRS is the first in the world to develop the Self-Launching MSS (SL-MSS). The difficulties in handling pier support brackets over water as well as on high piers prompted this development.

This system is able to transfer forward and mount the pier support brackets without any need of external lifting equipment or crane. The SL-MSS had been successfully used in the construction of several major bridge project worldwide and is widely sought after due to its low reasonable cost and operational efficiency.